Project Description

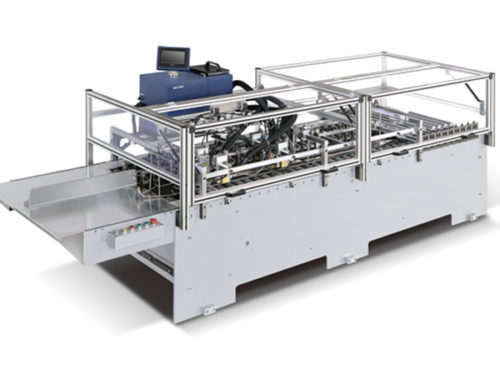

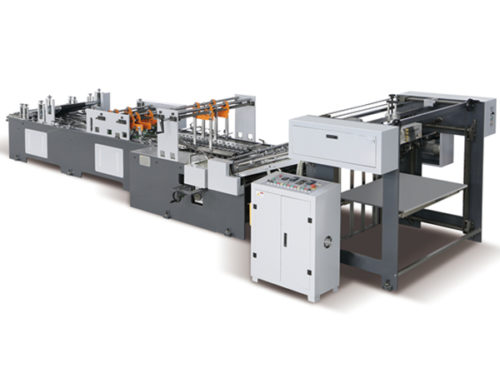

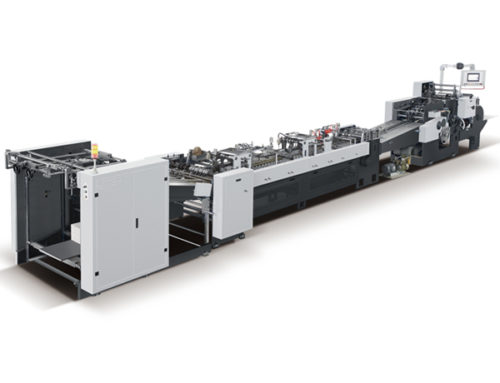

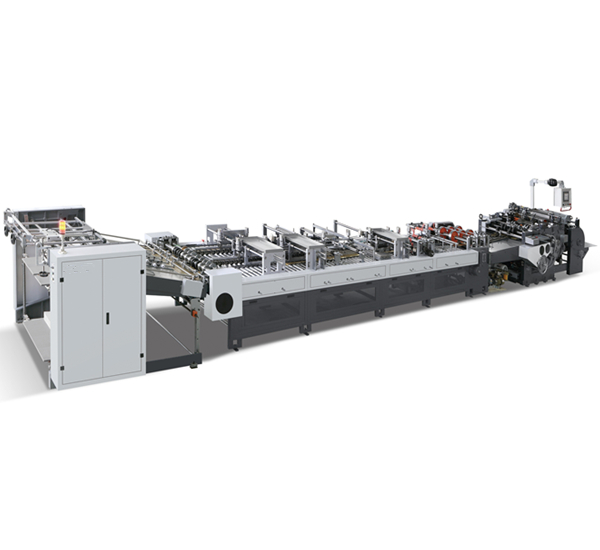

Fully Automatic Sheet Fed Paper Bag Making Machine SY-350

Feature:

- This machine is the ideal equipment to take the flat papers with original colors or printed well as raw materials to make into paper bags with square bottoms.

- Used for materials Brown paper, copperplate paper, white-plate paper and so on.

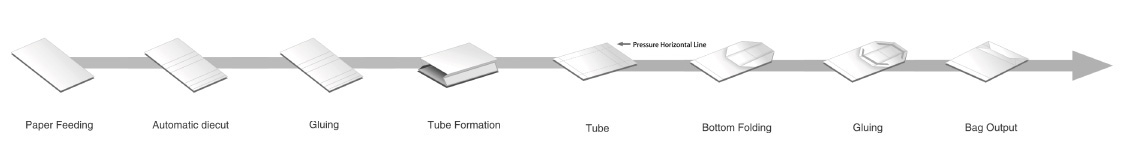

- Its technique process is about: the flat papers after printing are delivered into the driving parts for positioning through automatic paper feeder and press line with rolling press device

- And then make one-side glue, folding and positioning and sticking and conveying device will convey them into the bottom position and conduct press horizontal line, open bottom,make glue and press together and finally output finished bag products.

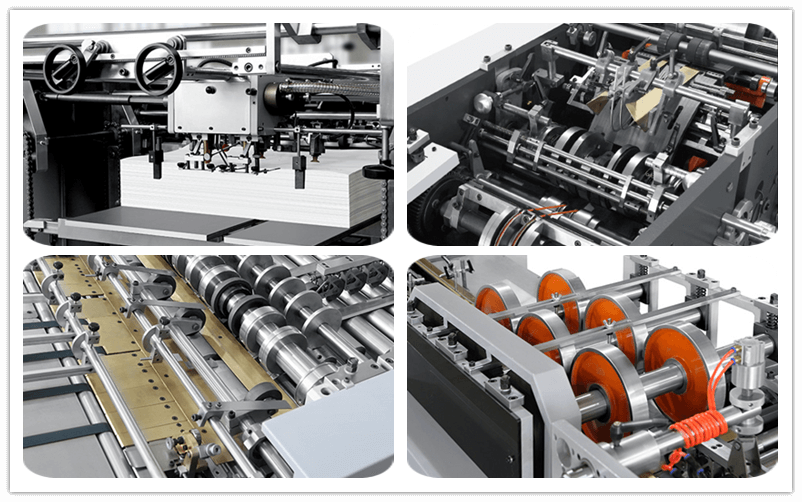

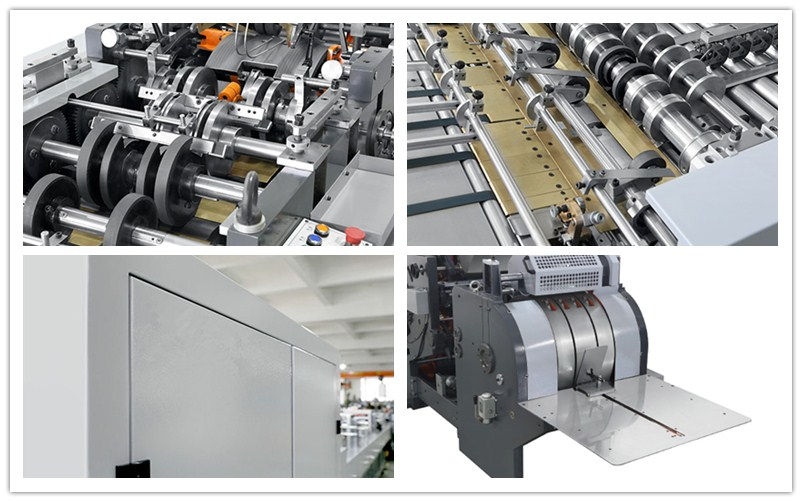

Machine Detail:

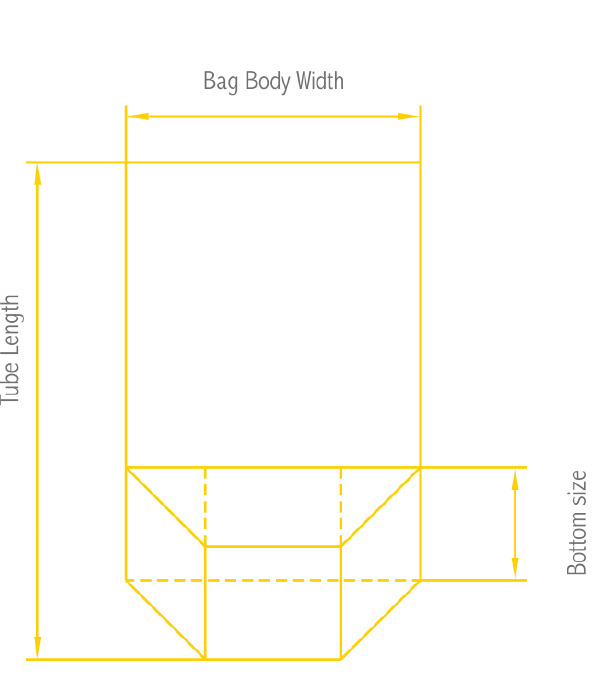

Paper Bag Sketch Map:

Working procedure:

Remarks: the mechanical speeds are different due to the different factors like paper quality, gram weight scope, printing result, whether stick with PP film or not, quality of sticking agent, paper size, climate and workshop environment

Technical Parameter:

| Model | SY-350/1040 | SY-450/1240 |

| Width scope of bag face | 180-350mm / 7.08-13.78inch | 260-450mm / 10.24-17.72inch |

| Organ height | 70-150mm / 2.75-5.90inch | 100-180mm / 3.94-7.09inch |

| Canister length of the paper bag | 290-600mm / 11.42-23.62inch | 380-620mm / 14.96-24.40inch |

| Paper width | 530-1040mm / 20.86-40.94inch | 620-1240mm / 24.40-48.82inch |

| Paper length | 290-600mm / 11.42-23.62inch | 380-620mm / 14.96-24.40inch |

| Paper weight range with unit | a. Brown paper (yellow brown and while brown):80-200g | a. Brown paper (yellow brown and while brown):80-200g |

| Paper weight range with unit | b. copperplate paper + PP peritoneum: 100-200g | b. copperplate paper + PP peritoneum: 100-200g |

| Paper weight range with unit | c. white paperboard: 180-250g; (take die cutting) | c. white paperboard: 180-250g;(take die cutting) |

| Paper weight range with unit | d. Grey paperboard + PP peritoneum: 150-250g(take die cutting) | d. Grey paperboard + PP peritoneum: 150-250g(take die cutting) |

| Product speed | 40-70 pieces/min | 40-70pieces/min |

| Glue type | watery glue( sticking the side can increase heat melting glue system) | Watery glue(sticking the side can increase heat melting glue system) |

| Total Power | 10kw | 13KW |

| Total Weight | 10T | 13T |

| Overall Dimension(L×W×H) | 14000×1800×1700mm | 15000×2100×1700mm |

1 Q:What is the machine warranty?

A: One year. We will provide maintenance support for any issue with the equipment. If the equipment are still under warranty, we will replace and repair the faulty parts free of charge and buyer will only need to pay for the shipping or air charges. In general we are able to ship the faulty party that are in stock within 1 day.

2 Q:What is the delivery time?

A:15-30days after get the payment.

3 Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

4 Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

5 Q:What’s the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

6 Q:Who is going to install the equipment?

A:Generally, as a buyer you will visit our factory for equipment training and installation but if needed we could also visit buyer’s factory. Buyer only need to pay for return air ticket and lodging expenses.

7 Q: Do you accept factory visiting?

A: We are highly greeting for your visiting.

Download here:

Share Our Product, Choose Your Platform!

Why Choose us

Inovative Products – one stop solution

Outstanding Quality – choose famous brand components

Customer Focus – give response within 24 hours

Create Value – partnership for long term

China Service office

Mr Sam Tong

sales@dsymachinery.com

+86 13736318590

Russia Service office

Mr Дмитрий Дубков

d_dubkov@mail.ru

+7 831 27580102

Thailand Service office

Mr Thakol Yajai

info@technotestsystem.com

+662 130 6900

Australia Service office

Mr Neil Phillips

neil@ercpackaging.com.au

+61 03 9354 2022