Project Description

A4 Paper Sheet Cutting Machine QZ-A

Feature:

- This machine is suitable for paper roll to slit and cut into A1 – A4 sheets.

- Also used for PVC, non woven roll, gold-silver paperboard, plain rainbow paper, the positioning laser transfer paper, white paper, plastic sheet and roll materials.

- This machine is suitable for all kinds of paper, paper and plastic compound, color printing compound plastic sheet and other large roll packaging materials cut. Widely used in paper processing industry, printing and packaging industry

- Adopts pneumatic automatic materials loading system with much easy operation and convenience

- Adopts down-up recurrent cutting with orderly finished products and without water caltrop;meantime,it can be used for horizontal cutting and vertical cutting at one time

- It adopts chinese servo motor for controlling constant-length cutting.

- It adopts PLC control, contact touch screen operation

- It adopts sensor for controlling transmission system, with photoelectric, gas together, it has the function of easy operation, high precision, good stability, low noise.

- This machine has the function of the frequency converter timing device, automatic counting, stop working by alarm ,magnetic powder tension control, can be vertically, adopt blower fan to get rid of waste

- It has the functions of high-precision of cutting,mauto collecting,etc . pneumatic loading combined with computer control be adopted for transmission section ,making it become much more steady operation

- It has the function of automatic stacking which is in order . Photoelectric auto tracing subtense system

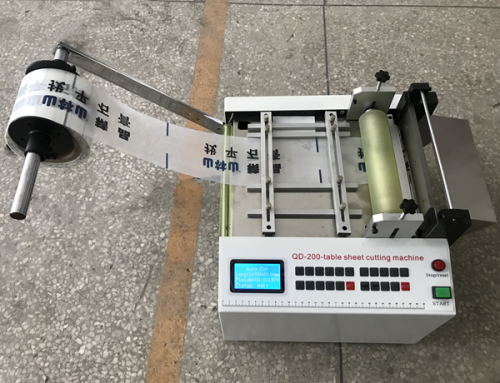

Machine Detail:

2 rolls A4 paper cutting machine:

4 rolls A4 paper cutting machine:

More video:

Technical Parameter:

| Model | QD-1200 |

|---|---|

| Max.width of cutting | 1100mm |

| Max diameter of material | Φ1200mm |

| Length of cutting | 20-1000mm |

| Speed | 30-200times/min |

| Precision | ±0.1mm |

| Weight | 2000kg |

| Overall dimension(LXWXH) | 5000x1900x1300mm |

1 Q:What is the machine warranty?

A: One year. We will provide maintenance support for any issue with the equipment. If the equipment are still under warranty, we will replace and repair the faulty parts free of charge and buyer will only need to pay for the shipping or air charges. In general we are able to ship the faulty party that are in stock within 1 day.

2 Q:What is the delivery time?

A:15-30days after get the payment.

3 Q:Can your company handle shipping for customers?

A:Yes, just give us destination sea port or container yard

4 Q:Do you inspect machines before packing?

A:Of course we do.we have QC department to debug the machine before packing

5 Q:What’s the payment term?

A:T/T 30% in advance, the balance paid before delivery. We also accept payment via West Union and L/C.

6 Q:Who is going to install the equipment?

A:Generally, as a buyer you will visit our factory for equipment training and installation but if needed we could also visit buyer’s factory. Buyer only need to pay for return air ticket and lodging expenses.

7 Q: Do you accept factory visiting?

A: We are highly greeting for your visiting.

Download here:

Share Our Product, Choose Your Platform!

Why Choose us

Professional R&D Team: Over 8 years experience with a top engineer team supported

Outstanding Quality: Only choose famous brand main electric components for production

ISO CE Approved: Professional certification bodies certify that the machines are of high quality

China Service office

Mr Sam Tong

sales@dsymachinery.com

+86 13736318590

Russia Service office

Mr Дмитрий Дубков

d_dubkov@mail.ru

+7 831 27580102

Thailand Service office

Mr Thakol Yajai

info@technotestsystem.com

+662 130 6900

Australia Service office

Mr Neil Phillips

neil@ercpackaging.com.au

+61 03 9354 2022